Purge Test Of High-Pressure Steam Purging Aluminum Target Board

Pipeline

After the purge process piping system is installed, it can be blown

by air or steam according to the working conditions of the working

medium and the degree of dirt on the inner surface of the pipe. The

general requirements for pipe purge are:

Equipment and pipes that are not allowed to be purged should be

isolated from the purging system.

Before the pipeline is purged, orifice plates, flange-connected

regulating valves, main valves, throttle valves, safety valves,

instruments, etc. should not be installed. For the above-mentioned

valves and instruments connected by welding, the bypass should be

used or the seal should be removed. Protective measures such as

pieces.

The order of purging should be carried out in the order of main

pipe, branch pipe, and drain pipe. The blown out dirt must not

enter the pipe that has been purged.

The dirt discharged by purging shall not pollute the environment,

and random discharge is strictly prohibited.

A restricted area should be set before purging.

After the pipeline has been purged qualified, other operations that

affect the cleaning shall not be carried out.

Air purge

1. In the process pipeline, all pipelines that transport gaseous

media are generally purged with air.

2. Air purging should use the large compressor of the production

unit, or the large container in the unit for intermittent purging;

the purging pressure should not exceed the design pressure of the

container and pipeline, and the flow rate should not be less than

20m/s.

3. When purging oil-free pipelines, use oil-free compressed air.

4. The inspection method of air purging is to inspect the target

board with white cloth or white paint at the exhaust port of the

purging pipe. No rust, dirt, or other dirt on the target board

within 5 minutes is qualified.

5. The angle between the purge port and the ground should be

between 30 degrees and 45 degrees. The pipe section of the purge

port and the pipe section of the purge port must be welded gently,

and the diameter of the purge port meets the requirements.

6. The length of each purge should not exceed 500 meters. When the

length of the pipeline exceeds 500 meters, it should be purged in

sections.

Steam purge

1. Steam purging is suitable for conveying power steam pipelines or

thermal pipelines. Non-thermal pipelines are not suitable for steam

purging because heat expansion and other issues are not considered

in the design.

2. Steam purging should be carried out with a large flow of steam,

and the flow rate should not be less than 30m/s.

3. Before steam purging, the pipes should be heated and drained in

time to check the thermal displacement of the pipes.

4. Steam purging should be carried out by steam-slowly rising warm

tube-constant temperature for 1h-purging-stop air cooling-reheating

pipe heating, constant temperature, second purging, such repetition

is generally not less than 3 Times.

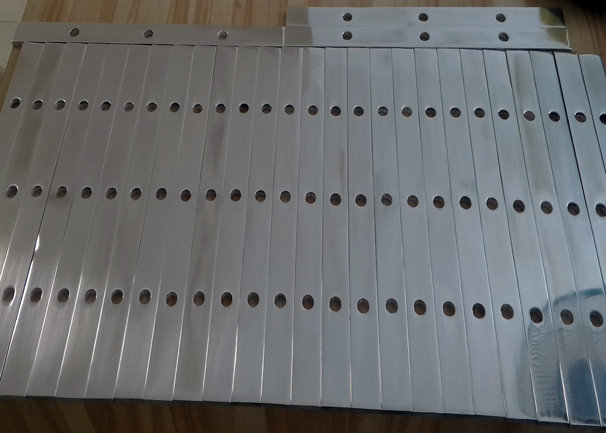

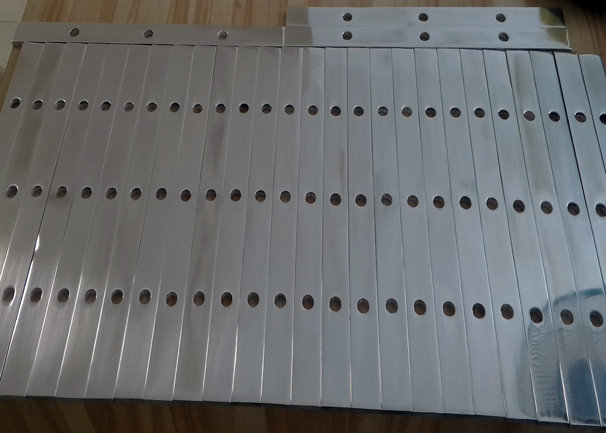

5. Medium and high pressure steam pipes and steam turbine inlet

pipes should be inspected with flat and clean aluminum target

plates and wooden target plates for low pressure steam. The target

plate is placed at the steam outlet and the target plate is

qualified if there is no dirt.

product description

| name | Aluminum target board |

| Material | Al ,Cu |

| use | Power plant pipe cleaning |

| Type | rectangle |

| thickness | 5mm, 6mm, 8mm, 10mm |

| size | According to requirements |

| Purging requirements | Equipment and pipes that are not allowed to be purged should be

isolated from the purging systemBefore the pipeline is purged,

orifice plates, flange-connected regulating valves, main valves,

throttle valves, safety valves, instruments, etc. should not be

installed. For the above-mentioned valves and instruments connected

by welding, the bypass should be used or the seal should be

removed. Protective measures such as pieces.

The order of purging should be carried out in the order of main

pipe, branch pipe, and drain pipe. The blown out dirt must not

enter the pipe that has been purged.

The dirt discharged by purging shall not pollute the environment,

and random discharge is strictly prohibited

|