Large Diameter 3LPE Oil Pipeline Anti Corrosion Spiral Welded Steel

Pipe

Spiral Steel Pipe

It is made by rolling low-carbon carbon structural steel or

low-alloy structural steel strip according to a certain spiral

angle (called forming angle) into a tube blank, and then welding

the tube seam together. It can be made with a narrower Strip steel

produces large diameter steel pipes. Its specifications are

expressed by outer diameter * wall thickness, and the welded pipe

shall be ensured that the hydraulic test, the tensile strength of

the weld and the cold bending performance must meet the

requirements.

Advantages of spiral welded pipe:

(1) Steel pipes of different diameters can be produced using strip

steel of the same width, and

steel pipes of large diameter can be produced from narrow strip

steel.

(2) Under the same pressure conditions, the stress of the

spiral welded seam is smaller than that of the straight seam, which

is 75% to 90% of that of the straight seam welded pipe, so it can

withstand greater pressure. Compared with the straight seam welded

pipe of the same outer diameter, the wall thickness can be reduced

by 10% to 25% under the same pressure.

(3) The size is accurate, the general diameter tolerance does not

exceed 0.12%, the deflection is less than 1/2000, and the ovality

is less than 1%. Generally, the sizing and straightening process

can be omitted.

(4) Continuous production is possible. In theory, long steel pipes

can be produced, with small head and tail loss, and can

increase the metal utilization rate by 6% to 8%.

(5) The equipment is light in weight and low initial investment. It

can be made into a trailer-type mobile unit to directly produce

welded pipes at the construction site where the pipeline is laid.

The production of spiral welded steel pipes can reflect the

advantages of high quality and high efficiency. The production

capacity of one spiral welded pipe unit is equivalent to 5-8 sets

of straight seam welded pipe equipment. How to make multiple pipe

coiling equipment production lines meet the same production

standard, that is, produce according to a unified production

process specification and quality assurance system to meet welding

quality Requirements and piping manufacturing grades will be an

arduous task.

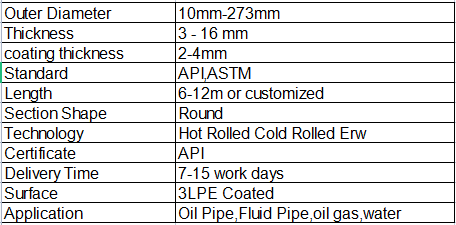

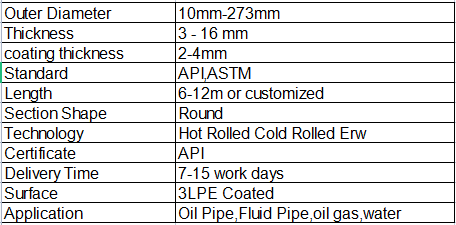

Product Description

Main Application:

1. Piling pipe;

2. Construction;

3. Water, Oil, Gas transportation;

4. Hydropower station pipe (Hydraulic Pipe);

5. Spiral welded steel pipes, which with Large diameter and strong

supply ability are widely used in construction and fluid

transportation.

Note:

1. Free sampling;

2. API 5L, ISO certified;

3. 100% after-sales quality assurance.

4. Quickly reply within 24 hours.

5. All other specifications of spiral welded steel pipes are

available according to your requirement !

Pipes can be Customized according to customer's requirement on

outside diameter and wall thickness with Galvanized coated or black

painted(3PE, FBE, 3PP) surface treatment.

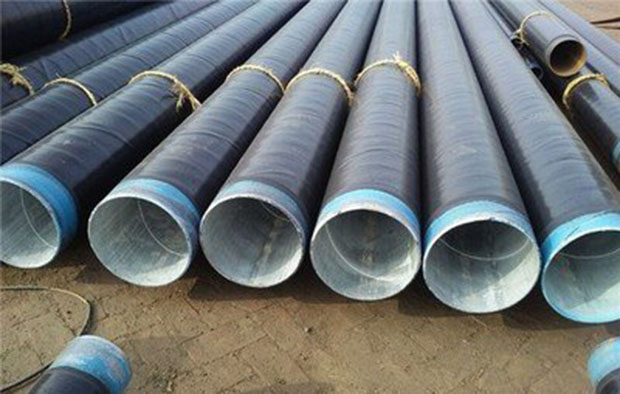

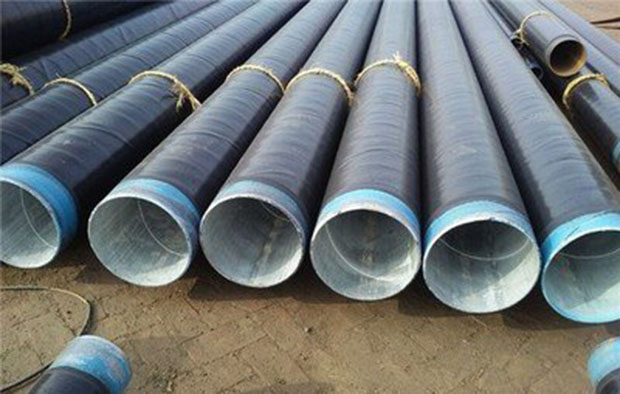

3PE anticorrosion generally consists of 3 layers:

The first layer of epoxy powder (FBE>100um)

The second layer of adhesive (AD) 170~250um

The third layer of polyethylene (PE) 1.8~3.7mm

In actual operation, the three materials are mixed and integrated,

and after processing, they are firmly combined with the steel pipe

to form an excellent anti-corrosion layer. Its processing methods

are generally divided into two types: winding type and round mold

wrapping type.

3PE anti-corrosion steel pipe coating (three-layer polyethylene

anti-corrosion coating) is a new type of anti-corrosion produced by

ingeniously combining the European 2PE anti-corrosion coating and

the epoxy powder anti-corrosion steel pipe coating (FBE) widely

used in North America. Steel pipe coating. It has been recognized

and used all over the world for over ten years.

The coating of 3PE anti-corrosion steel pipe is that the bottom

layer and the steel pipe surface are in contact with epoxy powder

anti-corrosion coating, and the middle layer is a copolymerized

adhesive with branched functional groups. The surface layer is

high-density polyethylene anti-corrosion coating.

The three-pe anti-corrosion coating combines the high

impermeability and high mechanical properties of epoxy resin and

polyethylene materials. So far, it is the globally recognized

pipeline anti-corrosion coating with the best use effect and the

best performance, which is used in many projects.